The tower structure was temporary art made in Italy using temporary rubber band joints.

This kind of cement used here is called "ceramic concrete" and it is a kind of phosphate alkali. The trusses are held together with black electrical tape and assembled as a test. The method of joining was improved by creating a jig and wrapping the union of parts like a bandage.

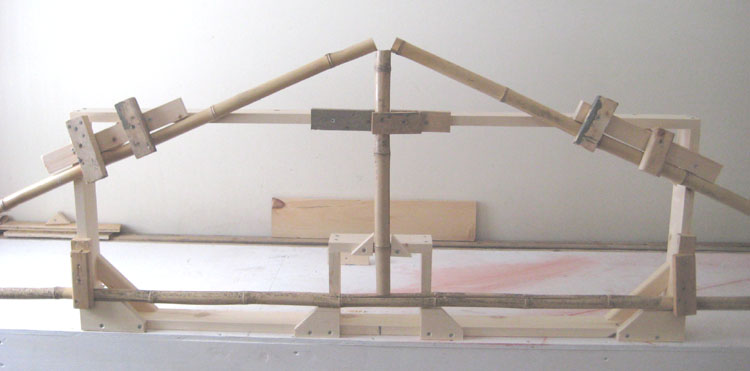

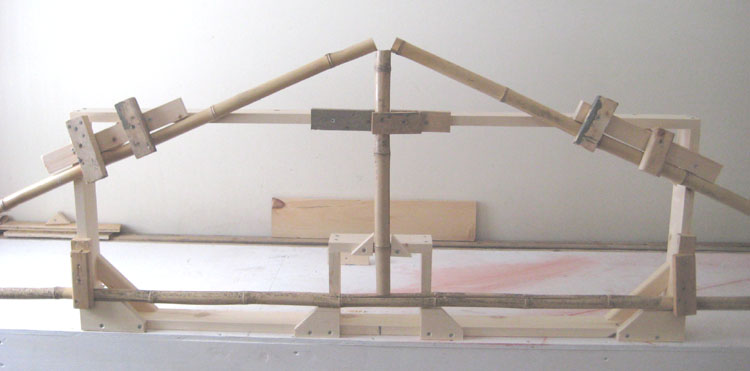

The jig is not expensive, it is only complicated enough to leave room to work the wrap around each joint. The gap at the peak is where the top purlin runs along the ridge line of the roof. A tensioned shaped catenary curve design for the roof plane can be created by various trusses using different center heights and a constant width. This design choice is made possible by the ease of bending bamboo purlins and will mimic the beautiful asian style of upward flared roof lines.

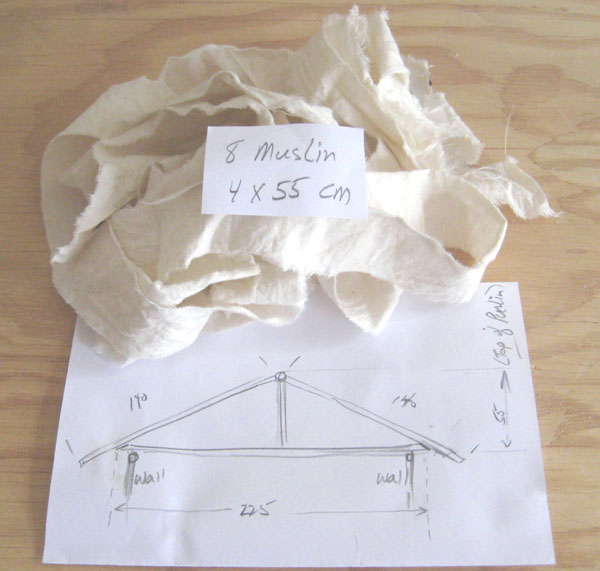

The first test of a wrapped joint was with burlap, the burlap proved too bulky, as a result of that, the second truss was made using muslin.

The joints are wrapped and do not use fiber packing as were the stuffed "burrito" style illustrated in the previous chapter examples, this technique is much faster.

Note that the joints will all disappear when the bamboo is quickly and completely wrapped with woven material soaked with binder, as was illustrated in the shed roof chapter. This is the simple reason why so many materials are suitable for wrap joints.

This truss is 2.6 m width, including 30 cm eves. The 5 cm ± which extends beyond the wall, on each end of the horizontal piece, is for lashing to a bamboo wall framework with the same 5¢ joint. Do not doubt the strength of these strips, many farmers have died because a small piece of their clothing became entangled in machinery and yanked them to untimely demise. If a hurricane has the power to rip apart these 5¢ joints, nothing will be left standing anywhere nearby.

This jig could also be made from bamboo. Noticing that the truss joints are easily reached and there is room to make full wraps, similar to bandaging a knee or wrist joint of a person. One will simply dig holes under joint locations if the jig is made from pegs hammered into the ground and the framework is done on hands and knees.

The 2.6 meter (8.5’) truss is shown clamped in its jig. Cut strips of muslin are at the mixing station, everything is ready at 29 minutes before the hour. The next step is measure and mix.

Here are those eight muslin strips, now impregnated with binder material. The ceramic concrete is mixed to a consistency slightly thinner than used with the concrete mixed with acrylic, a thin milk shake is closer to the consistency than the thin pancake batter description for acrylic and cement mix. This thinner aspect as well as material differences allowed for thorough penetration of the fiber by the binder material. It was almost as if there was a wetting agent or perhaps some ionic or acidic state which overcame the repulsive tendency of the fabric fiber surfaces. The fabric became thoroughly soaked at least as rapidly as in plain water.

The strips were first laid into a bucket of mix, one at a time. Avoid any twisting so the muslin doesn’t stick to itself (a small measure of slow motion care at this point is required because if the material folds on itself lengthwise it is difficult to separate while wearing rubber gloves). When the strip is wet, hold it above the small bucket with one hand and slide the excess off between the thumb and finger of the other hand. Then lay the strip flat on a piece of plastic and roll it onto a short piece of scrap bamboo, as in the photo above. Place the finished rolls back in the bucket and take the now easy to use strips to the frame jig where the joints are to be wrapped.

The eight strips shown above used approximately 280 grams of dry binder (10 oz). There are four joints on the truss, 280 ÷ 4 = each joint used 70 grams (2.5 oz). This material bought in small quantities cost at $10/lb, which is about €15/kg. The cost figures given on the laboratory product data sheets indicates a large reduction in cost could be realized from large volume purchasing. I’ve derived estimated figures ranging from 2 - 5¢ per joint, so, I named this the 5¢ joint. The cost will be similar whether it’s made from ceramic base material, acrylic mixed with portland cement, or plain glue.

Elapsed time from start is 23 minutes. Subtract time for photos and changing gloves etc and call this 25 minutes, including clean-up. The adjustable center clamps on the jig are handy because the bamboo is not exactly straight and varies in diameter, which is why the center piece is measured and cut after the other pieces are in place.

This 5¢ Tee joint cannot be made with a single 75¢ bolt.

Notice how the jig is made to have room to work around the joint.

The completed truss is shown removed from the jig a little less than an hour from start to finish. The temperature is 3.5° Celsius (38° Fahrenheit). It was less comfortable for the people displaced by earthquake in Pakistan but they could have benefited with a few hundred pounds of ceramic base cement for their bamboo fabrications.

One aspect of the manual is to provide insights for the huge number of small-scale enterprises which will be required to build hundreds of millions of shelters, in a timely fashion. The pattern jig shown at the left cuts identical bottom chords for this truss. The far angle guide is fixed in place the near one slides along the wood between the guides and is fixed at a chosen length, in this case, 2.25 meters. A common hand saw cuts a nice angle better than the one shown.

Clamp the bamboo in position and cut each end. Many identical pieces can be made and provided to the assembly area jig in size labeled kits. The same techniques are suitable for much easier wall assemblies. Keep in mind that there will always be some pieces that are cut to size during assembly in the jig, though many of those variable length pieces could be pre-cut a little short and the resulting planned gaps could be filled with binder and fiber.

Ferrocement.com urges caution in the direction of mass production for two reasons. First and foremost, uniqueness and art are integral to a healthy society, cookie cutter mass production is a problem with implications as deep as the human soul. Second, factory style production can stray toward either enforced labor exploitation or substitution of capital for labor to reinforce the class and caste systems, which are largely responsible for both unending war and the many environmental problems looming ahead.

This simple work has been of interest to scientists and other thinkers who understand the purpose as well as the idea of treating a chronic ailment before it becomes an unmanageable emergency. All suggestions will be appreciated. Send ideas or questions to contact@ferrocement.com.

I once jumped into a huge avalanche and grabbed my wife’s hands before she was swept away. We were deposited behind a tree with our legs just above a monster melting mountain as it roared by. If you have an idea, I know beyond doubt you should share it. Synergy is serendipitous.